Chase Center Lamp

Beginning with Design

All design ideas for the Chase Lamp originate from Studio 1 Thousand and Rush Design. NY Fab Shop is responsible for the execution of these designs and the creation of custom design tools to expedite that goal and to streamline into manufacturing.

Implementing the Power of Parametric Modeling

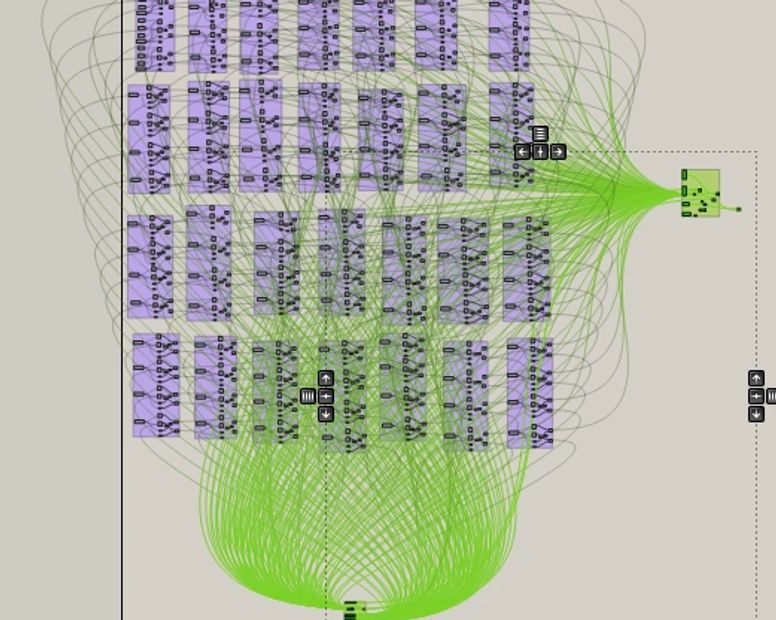

At the start of this project, Rush Design knew that it would be necessary to go through many iterations of the panel design. There are 28 panels with 16 features on both faces of each panel. The entire layout of the panels are a curved grid with variable panel sizing, which can make it very time consuming to orient and array all the features one by one, only to then have to go through another iteration, repeatedly. Jon Britton, from Rush Design, spent many hours perfecting the features that would house the power supply boxes and feed the power cables through the panels into the inlaid PCB on the front face of the panels. NY Fab Shop's job was to make a grasshopper definition to automate the process of not only orienting and arraying these features, but to then generate all of the 2d geometry necessary for programming the CNC machine for the manufacturing of the panels.

Panels with feature array and generated 2d geometry

The Template Panels

CNC Machining Templates

The Chase Center was still being built while this lamp was in the works. The architects, along with Rush Design and Studio 1 Thousand, devised a way to install template panels and build the ceiling around them, to later be swapped out with the final panels.

The templates were made with a large opening in the middle, with all the unistruts and hardware attached. This allowed the crew on site to access the back of the panels and install them into the ceiling.

Crating

Once everything was all assembled and crated, they were sent off to San Fransisco, CA from the Brooklyn location of Rush Design.

Someone decided to throw Steve into the crates before they shipped! ¯\_(ツ)_/¯

Template panels installation on site.

Machining, Painting, Assembling and Crating Final Panels

Panels Primed Waiting for Paint

Final Paint Application

Machining Front Side of Painted Panels for PCB

Front Side Feature

Fully Machined Panel

Fully Assembled Panel with Hardware

Off to California!

Final Panels Being Installed on Site

Copyright © 2025 NY Fab Shop - All Rights Reserved.